Beta-Glucan Breakdown | Digesting the Power of Mushrooms.

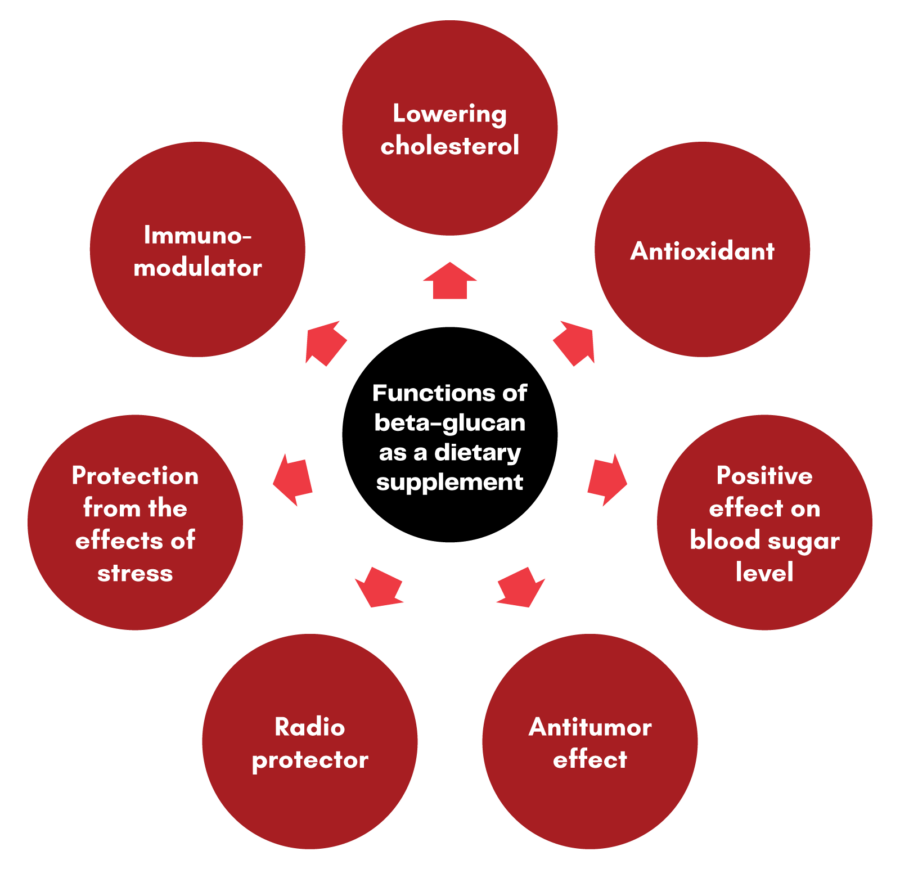

Did you know that not all mushroom supplements are created equal? Beta-glucans (β-glucans) are part of a host of powerful compounds that give functional mushrooms their unique and beneficial properties.

These natural compounds are found in mushrooms, yeasts, and certain grains – but mushrooms contain some of the most beneficial and thoroughly researched forms for your immune system. Think of β-glucans as your immune system’s personal trainers, helping to keep your natural defenses in top shape!

Let’s dig in

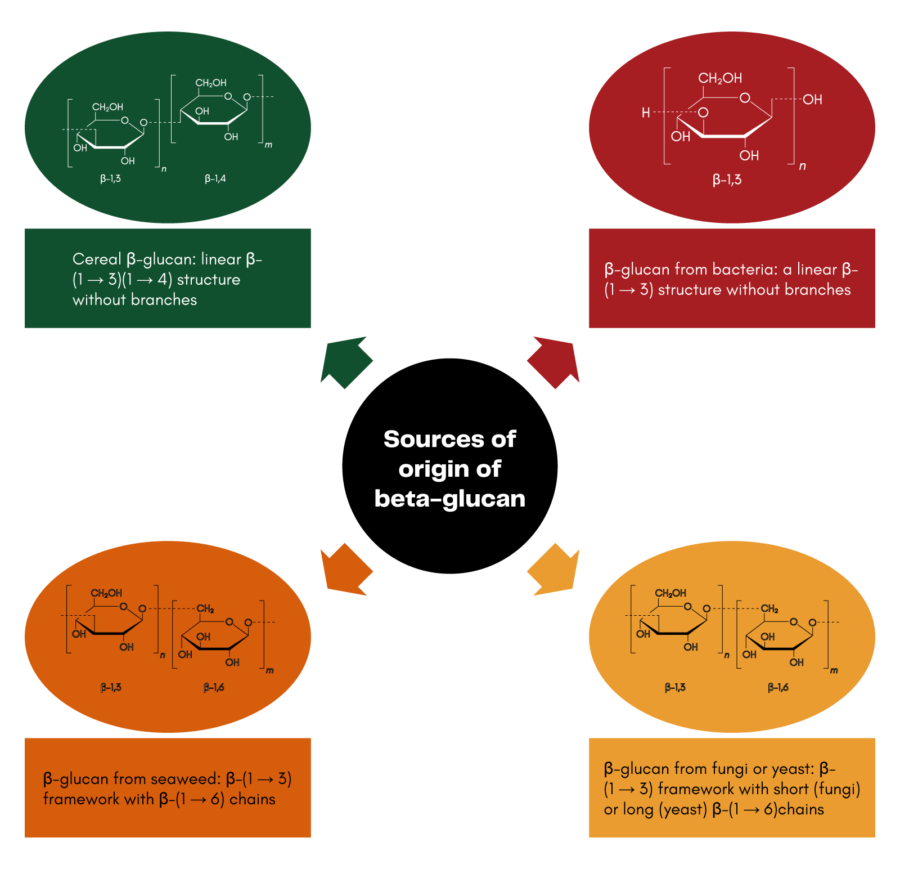

β-glucans are naturally occurring polysaccharides – complex carbohydrate molecules found in various natural sources including mushrooms, yeasts, seaweed, and certain grains like oats and barley. Think of them as building blocks that make up cell walls in these organisms, much like bricks form the structure of a building.

What makes mushroom beta-glucans special?

While β-glucans exist in many forms, mushroom β-glucans have unique structural characteristics that set them apart. The β-glucans found in mushrooms have a specific molecular structure that’s different from those found in other sources. For example, mushroom β-glucans typically have a branched structure with both 1,3 and 1,6 linkages, while oat β-glucans have a simpler linear structure with 1,3 and 1,4 linkages.

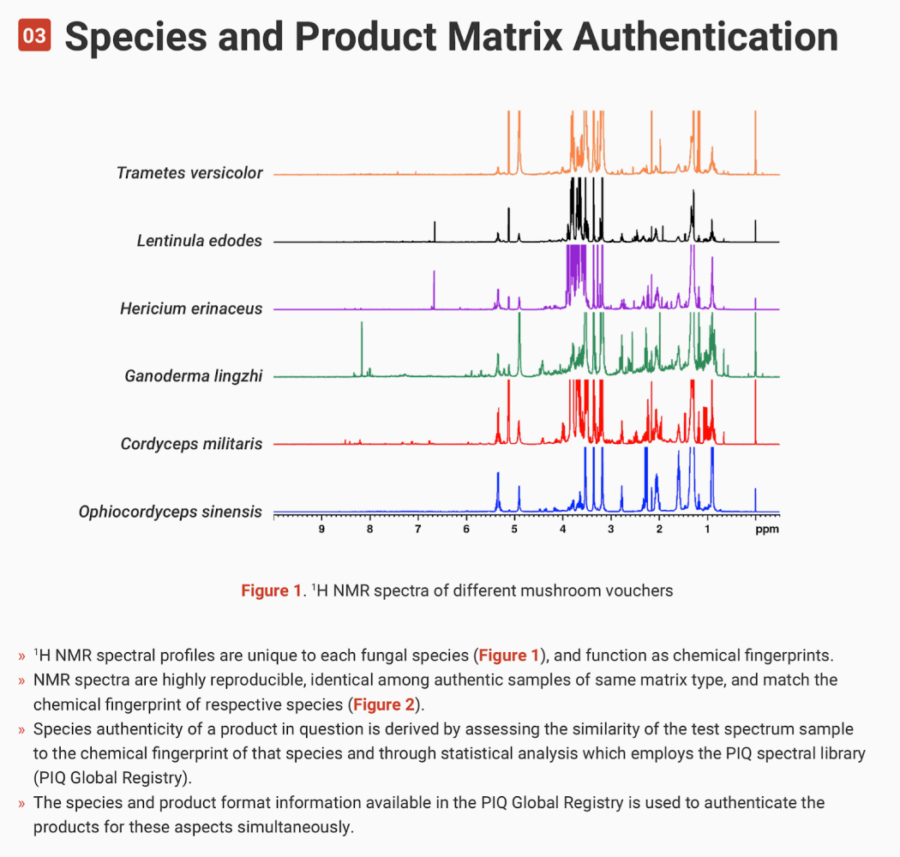

At Nammex, we’ve spent over four decades studying and analyzing β-glucans in mushrooms. Through our research and development program, we’ve validated specific testing methods to identify and measure these compounds in our extracts. This scientific approach allows us to ensure consistent quality and potency in our products. We continue to work on alternative methods of analysis for mushroom β-glucans through our partnership with Purity IQ utilizing Nuclear Magnetic Resonance technology.

Learn more about Purity-IQ‘s Mushroom β-Glucan Authentication and Quantification Using NMR Spectroscopy here.

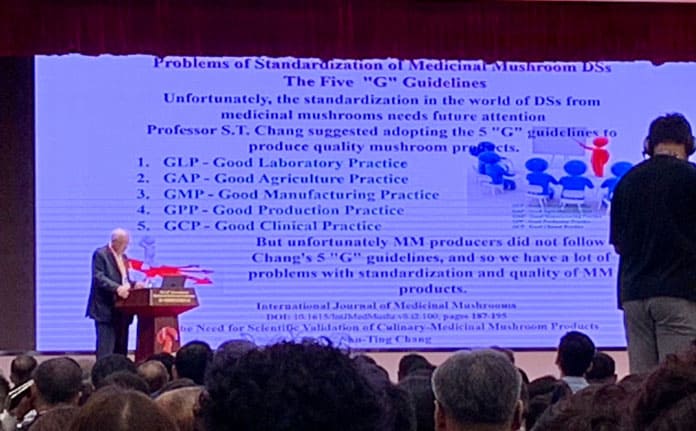

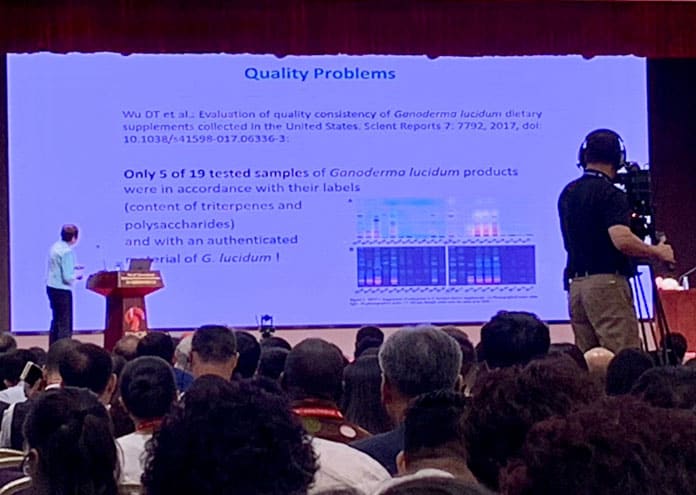

The importance of testing

Not all mushroom products contain the same levels of β-glucans. This is why testing is crucial. Through our analytical program, we’ve established what we call the “Nammex mushroom testing fingerprint” which includes β-glucan testing as an integral part of the matrix. This testing ensures that when you choose a Nammex product, you’re getting mushroom extracts with verified β-glucan content in addition to other important fungal compounds such as ergothioneine and ergosterol and other species specific markers for quality and potency. The methods of qualification used by the Nammex Lab are now being integrated into commercial labs, and standard setting organizations. Nammex is engaged in collaborative validation and method transfer with these organizations to continue setting the bar for quality in the Mushroom category.

Why source matters

The source, growing conditions and post harvest handling of mushrooms can significantly impact their quality. Nammex’s products are born from the Chinese Tradition of mushroom cultivation and processing that dates back thousands of years with the advantage of the technological advances China has made through massive investment in their farmers and specialty crops. We focus entirely on mushrooms, allowing us to specialize in maximizing the presence of these beneficial compounds in our extracts and it is all under Organic Certification, at scale and runs like a well oiled machine.

Understanding beta-glucan testing

When evaluating mushroom products, it’s important to know that β-glucan content can vary significantly. Looking at the top 5 species for Nammex’s 1:1 extracts; Lion’s Mane, Reishi, Chaga, Cordyceps,and Turkey Tail there is a range of no less than 8mg/g for Chaga and Cordyceps. Lion’s Mane has 30mg/g. Reishi has a specification of no less than 35mg/g and Turkey Tail is NLT 45mg/g. Nammex has a tradition of collaboration with mushroom analytical sciences and has long worked with the company Megazyme who specializes in carbohydrate testing and science. Dr. Barry McCleary its founder has a seminal paper published in the Journal of the AOAC which is a must read and an independent analysis of β-glucan in Mushrooms and Mycelium fermented Grain; Measurement of β-Glucan in Mushrooms and Mycelial Products . The Nammex Lab uses the Megazyme K-YBGL kit as do other third party labs to validate β-glucan content. Nammex goes a step further and also runs the AOAC Starch Test in tandem when analyzing commercial products to determine the amount of carrier or grain in non Mushroom products made from mycelium fermented grain. The alpha-glucan (α-glucan) results tend to follow the starch results with high amounts of alpha and starch in all mycelium fermented grain products yet low to no starch in true mushroom products with β-glucans percentages as noted above, quite high.

Looking to the future

As research continues to advance our understanding of β-glucans, we remain committed to maintaining the highest standards in mushroom extract production. Our ongoing research and development efforts help us stay at the forefront of mushroom science and analysis. We continue our work with NMR and Purity IQ to be able to strengthen the integrity of testing by adding more complimentary and fit for purpose methods.

Through our commitment to quality and scientific analysis, we continue to lead the way in understanding and properly identifying these fascinating compounds in mushroom products.

If you have any questions on the above info, please shoot us a direct message. We would be happy to help.

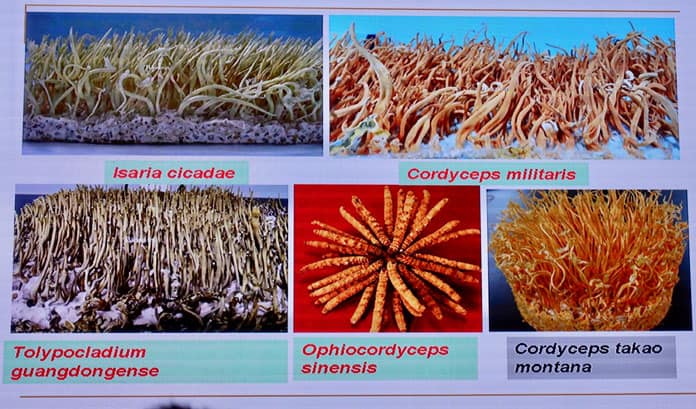

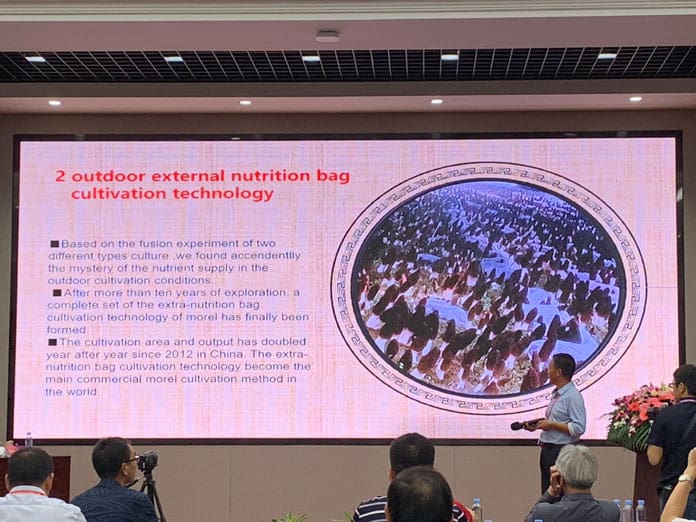

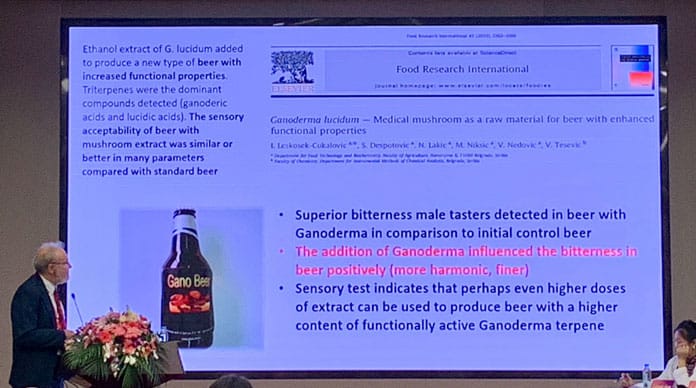

One theme we observed throughout the course of our recent visit to our mushroom growers in China was the emphasis on educating people in different aspects of the mushroom industry, from research to cultivation. With the recent efforts to lift more citizens out of poverty, the business of researching and growing quality mushrooms is being highlighted as a path to a better life. Because of China’s long history of medicinal use of functional mushrooms and the deep knowledge developed over centuries, this path to prosperity has significant appeal to many people beyond the financial motivation.

One theme we observed throughout the course of our recent visit to our mushroom growers in China was the emphasis on educating people in different aspects of the mushroom industry, from research to cultivation. With the recent efforts to lift more citizens out of poverty, the business of researching and growing quality mushrooms is being highlighted as a path to a better life. Because of China’s long history of medicinal use of functional mushrooms and the deep knowledge developed over centuries, this path to prosperity has significant appeal to many people beyond the financial motivation.